The ‘Write’ Way to Manufacture

The Pen Company of America (PCA) is another family-owned firm that’s bullish on domestic manufacturing. The Garwood, NJ, company has been in business since 1928. Today, it mass-produces a wide variety of writing instruments, including pens and industrial markers, in a 50,000-square-foot factory that’s highly automated.

“We have never manufactured products outside the United States,” claims Colleen Shea, vice president of sales at PCA, who runs the company along with her father and two brothers.

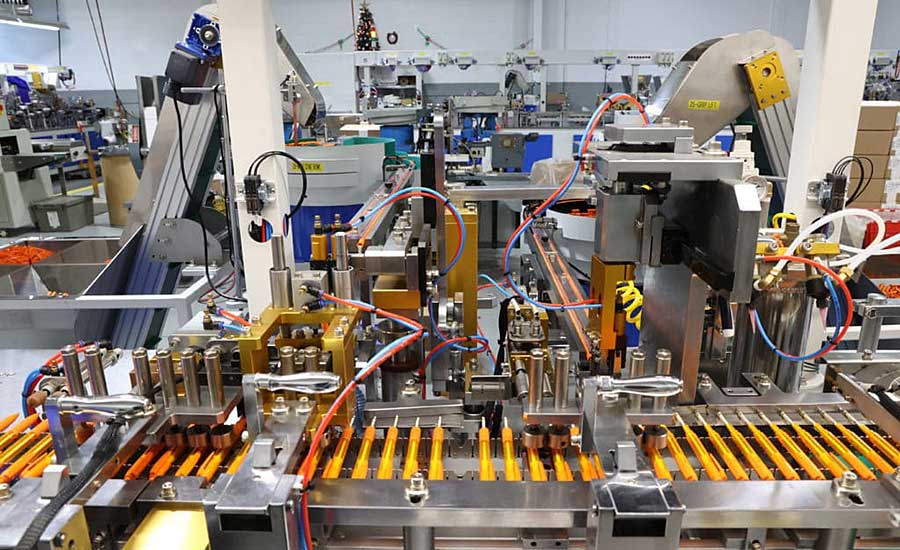

Automation enables U.S. manufacturers to go head to head with offshore competition. Photo courtesy Pen Company of America

Automation enables U.S. manufacturers to go head to head with offshore competition. Photo courtesy Pen Company of America

“As a fourth-generation writing instrument manufacturer, we have always worked hard to keep all our production domestic,” explains Shea. “Many of our pens are customized for the promotional industry.

“In that arena, we are the only manufacturer whose entire line of metal and plastic pens is domestically made,” explains Shea. “While others moved offshore over the last few decades, we have dedicated our time, energy and resources to find creative ways to keep manufacturing in America.”

The company produces around 30 different styles of pens and markers. In addition, it makes internal metal components for other companies, such as Fisher Space Pen Co., which assembles its specialty products in Boulder City, NV. PCA also molds plastic parts that a medical device firm uses to produce surgical skin markers.

“The majority of our business involves custom-made pens that are used for promotional purposes,” says Shea. “They contain unique customer names, logos, colors and designs. We supply everyone from large banks to small mom-and-pop coffee shops.

“We are vertically integrated,” Shea points out. “We do all of our plastic-injection molding in-house, in addition to making the metal writing cartridges. We also do all printing, laser engraving and decorating ourselves. We even make our own springs, and we produce our own heat-transfer film, which is used for decorating pen barrels.”

PCA operates three assembly lines that mass-produce an average of 30,000 pens a shift or as many as 300,000 units a week.

“All our metal pens have ‘USA’ embossed in them,” says Shea. “All our plastic pens have ‘USA’ molded into them. Our standard, gift and executive boxes all indicate ‘Made in the USA.’ Even the boxes themselves are made domestically.”

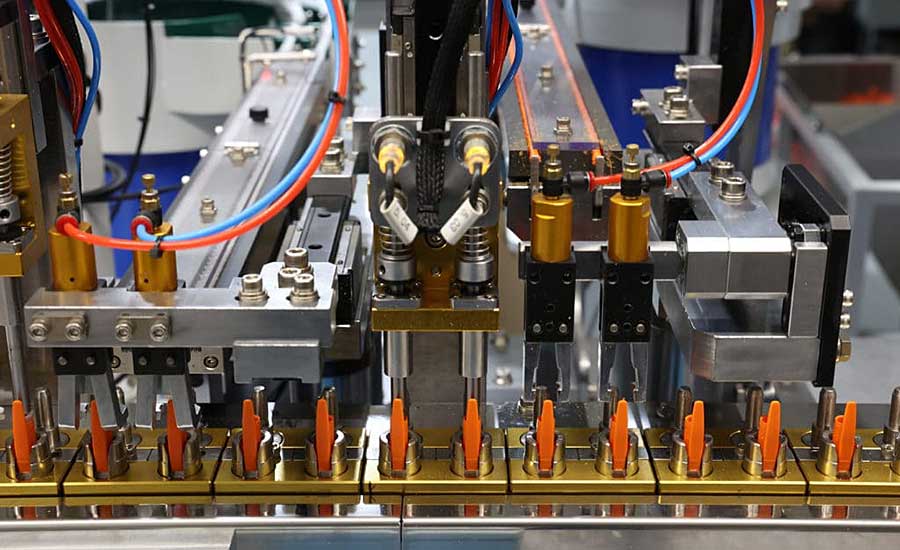

A typical plastic pen consists of six main components, including the barrel, writing cartridge, a plunger and ratchet mechanism, a spring, a tip and a clip. Metal pens are more complex and contain up to 14 components.

“All of our production processes are automated, including robots for assembly and pick-and-place applications,” says Shea. “Automation plays an important role in keeping our pricing stable and constant. That’s the only way we can compete with imported products.

The writing instrument industry is very competitive, because pens are a commodity product,” explains Shea. “We pride ourselves on high quality and fast delivery times.

“A lot of metal pen companies have moved production offshore, including our biggest competitor,” notes Shea. “Unlike those companies, most of our products are delivered within seven to 10 business days.

The writing instrument industry is very competitive, because pens are a commodity product. Photo courtesy Pen Company of America

“Another thing that sets us apart is customer service,” claims Shea. “Many small companies in our industry have been bought up by larger firms that moved customer service offshore. We are more nimble and have a definite advantage in that regard.

“With domestic production, we can react quickly to customers’ needs,” says Shea. “When a customer needs 100,000 custom pens in a few weeks or a specially molded pen, we have the ability to fulfill these orders much quicker than the imported products. The disruption in the supply chain over the past several years has given us a unique competitive advantage.

To succeed, domestic consumer products manufacturers must excel at customer service, delivery and quality. Photo courtesy Pen Company of America

“It’s not difficult for us to compete against offshore manufacturers,” adds Shea. “Even if we’re a little more expensive, we excel at customer service, delivery and quality. However, we have to be creative and stay one step ahead in terms of finding ways to improve our costs.

“Overall, this is a good time to be an American manufacturer, because the COVID pandemic exposed a lot of supply chain gaps and deficiencies,” concludes Shea. “We have seen a resurgence and appreciation for U.S. manufacturing.”